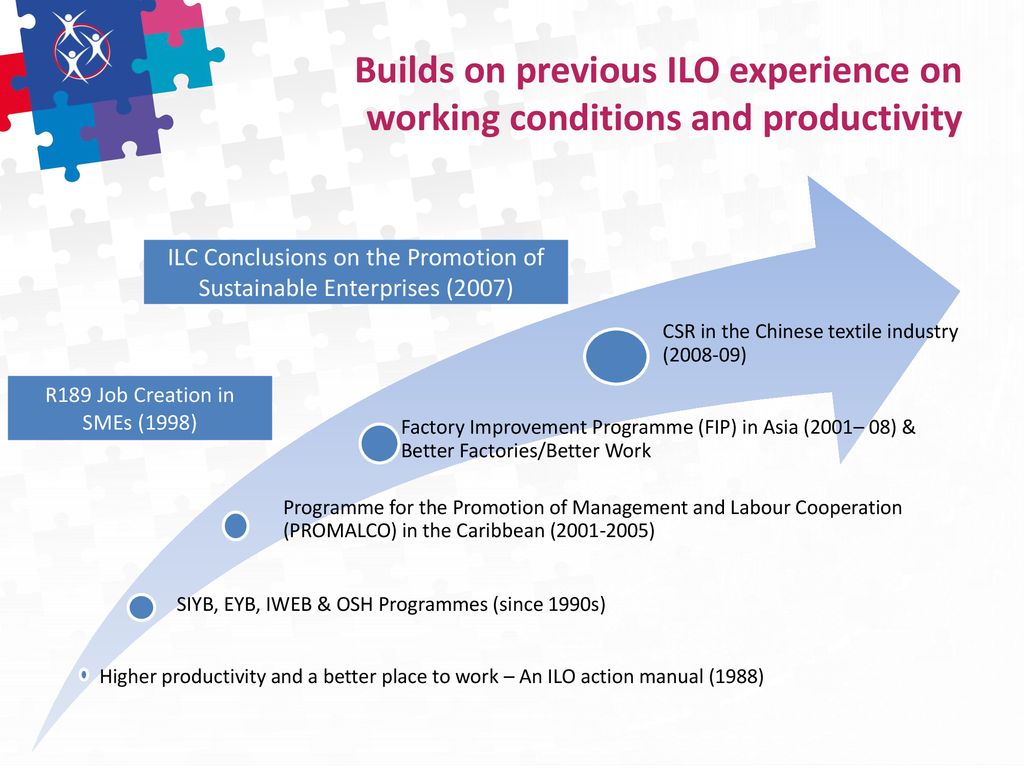

ILO Better Factories Cambodia Remediation Modular Training Program Facilitator’s Manual. Credit for the establishment of the modular training approach must go to ILO’s Factory Improvement Programme. The program assists in the development of local factories’ capacities in the areas covered by ILO’s Declaration on.

For a P-class blade server, you will need to connect the 'dongle' cable to the front of the blade. Naruto shippuden episode 159 english subbed. Connect an ethernet client to the RJ45 connector and configure it for a static IP address. ILO will detect the cable presence and assume a static IP address of 192.168.1.1 on the front cable. You can open a browser and then log into iLO at that address. From there, using the iLO Remote Console, reboot the host, enter iLO RBSU during POST, and select 'Set to factory defaults' and exit.

Of course, this will preempt your Remote Console session. Disconnect the dongle, and wait a couple minutes for iLO. From that point on, iLO will become a DHCP client on the regular iLO network. Using the DNS name on the front tag, browse to the client and have at it.

Exception: if you have the enclosure configured to use Enclosure Static IP addressing for the bay, i.e., iLO in bay 1 gets xxx.yyy.zzz.1 and bay 2 gets xxx.yyy.zzz.2 and so on, the blade will assume that address instead of DHCP.

Improving Factory Working Conditions A commitment to safety, fairness, dignity and respect We partner with all of our suppliers to ensure safe, fair and healthy working conditions for the individuals who create our clothes. Together, we’re building the capacity of our suppliers to manage and improve their practices, designing industry-leading programs to improve worker and manager relations, assessing and improving working conditions to meet legal and international standards and increasing transparency about all of our efforts.

Our Approach Consumer trends and expectations are placing greater demands on production timelines and capabilities—which can ultimately affect the individuals working in the garment industry. To help manage these broad shifts in the industry, we continue to integrate policies and programs into our core business and form partnerships across the apparel industry to ensure that the people in our supply chain work in safe, fair conditions. Since launching our Supplier Sustainability program in 1994, we have transformed our approach to improving facility working conditions by developing innovative programs that go far beyond assessing and remediating issues in our approved facilities. Our approach to improving working conditions is based on transparency, partnership and innovation. We believe that by working together, we can achieve our commitments to improve workers’ well-being, protect human rights, reduce environmental impacts and unleash improved business performance.

Our Supplier Sustainability efforts thus far have primarily focused on issues at cut-and-sew facilities where we have direct relationships and greater influence to drive improvements. We also monitor, assess, remediate and disclose their supporting facilities, such as laundries, embroideries and screen printers. However, we are evolving our strategy to address issues in other parts of our supply chain, including areas where we have less direct influence but nonetheless see opportunities to improve working conditions.

For instance, we are working with our strategic mill suppliers to assess their working conditions and build their capacity to proactively mitigate risks, and we are seeking to improve conditions in the cotton sector through our partnership with the Better Cotton Initiative. Achieving this requires innovation and closer partnership with suppliers and their facilities that manufacture our branded product.

At the same time, more assistance, better tools and added capability building services are provided to suppliers to help them improve their sustainability performance. One of our responsibilities in a partnership model is to clearly establish and communicate all of our expectations to our supply chain partners. To that end, we have evolved our Code of Vendor Conduct (COVC) to provide our supply chain partners with more clarity on our standards, goals and expectations. Our – which is a comprehensive manual that provides guidance and insight into how facilities can meet the standards outlined in our COVC – is reviewed on an annual basis to reflect best practices. It is incorporated into our Vendor Compliance Agreement, which is signed by all our manufacturers.

In this second installment, Matsu has naginata and has the power to summon animals. Kasuga relies on four kunai with hand sharpening connected while new skills related to the energy of the lamp cord. Chosokabe Motochika and Mori Motonari can be played not only be NPC.  The same thing can be said Sarutobi Sasuke and Kasuga. In addition, the problem of 'character clone' is omitted; in the first game, Uesugi Kenshin and Matsu share the same set of movements and weapons.

The same thing can be said Sarutobi Sasuke and Kasuga. In addition, the problem of 'character clone' is omitted; in the first game, Uesugi Kenshin and Matsu share the same set of movements and weapons.